- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-28 Origin: Site

Nothing ruins an outdoor adventure faster than waking up in a puddle inside your tent. When the weather turns nasty, your tent fabric becomes your first line of defense against the elements. But with so many materials claiming to be "waterproof," how do you know which ones actually deliver?

After years of field testing and research into tent fabric technology, we've compiled this comprehensive guide to help you understand what makes certain materials truly waterproof and which options will keep you dry when it matters most.

| Fabric | Hydrostatic Head (HH) | Weight | Pros | Cons |

|---|---|---|---|---|

| Cuben Fiber (Dyneema Composite) | ≥ 6000 mm | Ultra-light | Ultimate waterproofing, ultra-light | High cost |

| Silicone-Coated Nylon | 4000–5000 mm | 300–400 g/m² | Lightweight, tear-resistant | Slightly less abrasion-resistant than PU |

| PU-Coated Polyester | 2000–3000 mm | 200–300 g/m² | Excellent value, low cost | Heavier than silicone-coated fabrics |

| Poly-Cotton Canvas | ≥ 1500 mm | 500–800 g/m² | Breathable, durable | Very heavy, bulky |

| High-Density Oxford/RPET | 1500–2500 mm | 250–400 g/m² | Recycled, eco-friendly | Moderate waterproofing |

Understanding tent fabric performance requires knowing three key metrics that determine how well your shelter will protect you from rain and moisture.

Hydrostatic head measures how much water pressure a fabric can withstand before it starts leaking. Think of it as a tall column of water pressing down on the fabric until water finally breaks through. The measurement is given in millimeters—the taller the water column before breakthrough, the more waterproof the fabric.

Generally, fabrics with a rating of 1,000 mm or higher are considered waterproof. However, for serious camping, you'll want much higher ratings, especially for prolonged exposure to rain.

Denier measures the thickness of the individual fibers used in the fabric. Higher denier numbers indicate thicker, more durable materials that resist tears and punctures better. However, they also tend to be heavier.

Most tent fabrics aren't naturally waterproof—they achieve water resistance through specialized coatings. The three main coating types are silicone, polyurethane (PU), and polyether urethane (PE), each with distinct advantages and drawbacks.

Cuben fiber represents the pinnacle of waterproof tent technology. This laminated material sandwiches ultra-strong Dyneema fibers between waterproof film layers, creating a fabric that's both incredibly light and completely impermeable to water.

Pros:

Exceptional waterproof performance (6000 mm+ HH rating)

Ultra-lightweight for backpacking

UV resistant and extremely strong

Won't absorb water or stretch when wet

Cons:

Very expensive (can cost 3–5x more than standard fabrics)

Lower abrasion resistance than coated fabrics

Crinkly texture some find annoying

Best For: Alpine mountaineering, ultralight backpacking, and situations where weight is critical and budget is flexible.

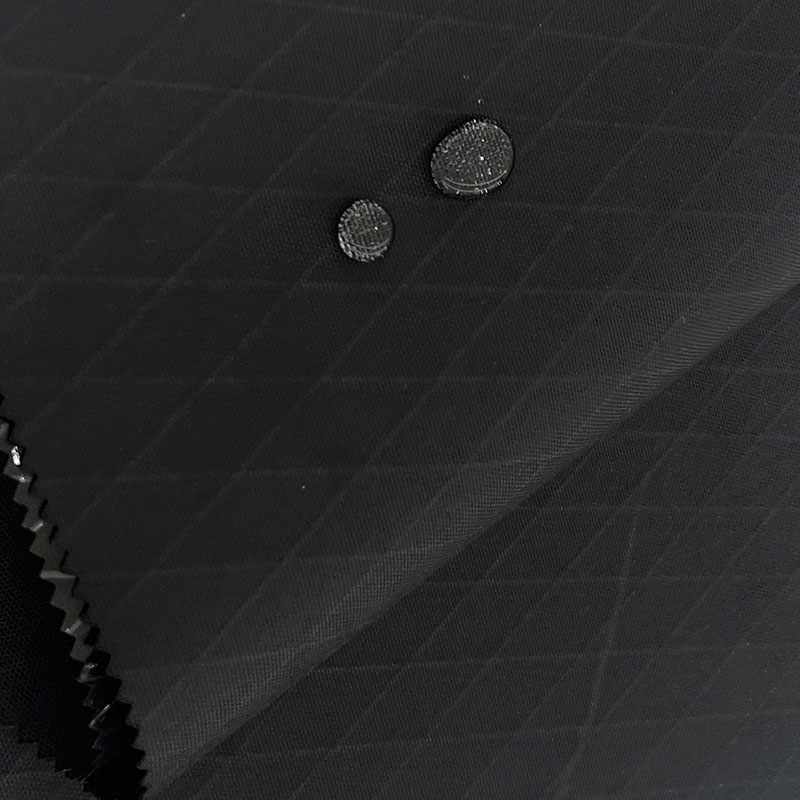

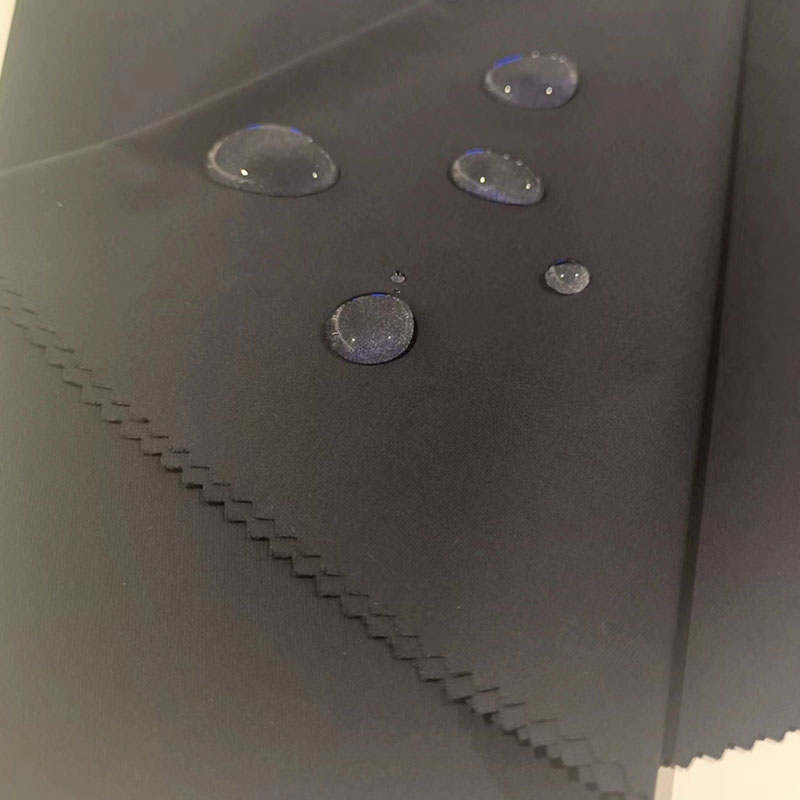

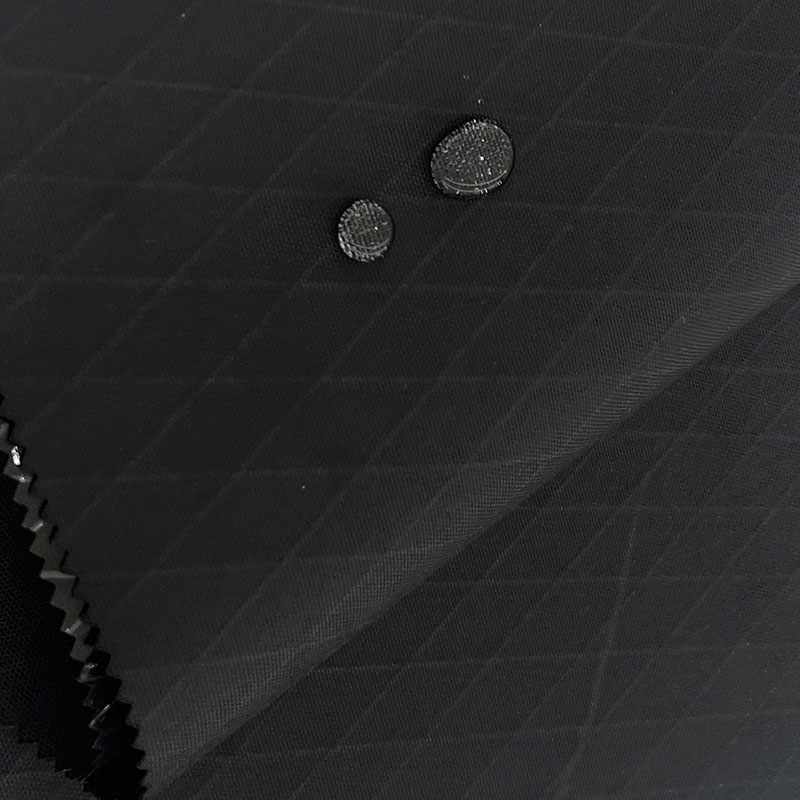

Silicone-coated nylon strikes an excellent balance between waterproof performance, weight, and durability. The silicone coating creates a hydrophobic surface that causes water to bead up and roll off rather than soaking through.

Pros:

Excellent waterproof performance

Lightweight and packable

Superior tear strength compared to PU-coated fabrics

Highly resistant to mold and mildew

Won't stretch significantly when wet

Cons:

More expensive than PU-coated alternatives

Cannot be seam-taped (requires manual seam sealing)

Can be slippery when used for tent floors

Best For: Multi-day hiking, rainforest camping, and situations where long-term reliability is important.

Polyurethane-coated polyester is the workhorse of the tent industry. While not as waterproof as silicone or Cuben fiber options, it offers solid performance at an affordable price point.

Pros:

Budget-friendly option

Can achieve high HH ratings with thick coatings

Can be seam-taped at the factory

Fire retardants can be added to meet safety standards

Cons:

Absorbs water over time, leading to eventual leakage

Prone to hydrolysis (coating breakdown) over years

Can stretch and sag when wet

More susceptible to mold and mildew

Best For: Family camping, car camping, and budget-conscious buyers who don't need extreme performance.

Canvas combines traditional materials with modern waterproof treatments. While heavy, it offers unique advantages for certain camping styles.

Pros:

Excellent breathability reduces condensation

Very durable and long-lasting

Comfortable interior climate

Natural insulation properties

Cons:

Very heavy and bulky

Absorbs water and becomes even heavier when wet

Requires complete drying before storage to prevent mildew

Lower waterproof ratings than synthetic options

Best For: Semi-permanent camps, glamping, car camping where weight isn't a concern, and hot climate camping.

Oxford fabric and recycled PET (RPET) materials represent the eco-friendly option in tent fabrics. These tightly woven fabrics offer decent waterproof performance while addressing sustainability concerns.

Pros:

Made from recycled materials

Good durability and tear resistance

Moderate waterproof performance

Environmental benefits

Cons:

Lower waterproof ratings than premium options

Often requires additional seam sealing

Limited availability in ultra-lightweight versions

Best For: Eco-conscious campers, sustainable travel, and situations where environmental impact is a priority.

Even the most waterproof fabric won't keep you dry if water leaks through the seams. Every needle hole created during tent construction creates a potential leak point.

Seam Tape: Factory-applied waterproof tape covers sewn seams on the inside of the tent. This method works well with PU-coated fabrics but doesn't adhere properly to silicone-coated materials.

Silicone Sealant: Liquid silicone applied to seams creates a waterproof barrier. This method is often required for silicone-coated fabrics and can be done at home for maintenance.

Footprint: A groundsheet placed under your tent provides extra protection against ground moisture and sharp objects. Make sure it doesn't extend beyond the tent floor, as this can channel rainwater underneath.

Maintenance: Regular cleaning, proper storage, and periodic re-treatment of waterproof coatings will extend your tent's waterproof performance significantly.

Backpacking: Prioritize Weight and Performance

For backcountry adventures, look for fabrics with HH ratings of 4000 mm or higher while minimizing weight. Silicone-coated nylon or Cuben fiber are ideal choices if your budget allows.

Car/Family Camping: Value and Comfort

When weight isn't a concern, PU-coated polyester or canvas options provide excellent value. HH ratings of 2000–3000 mm are sufficient for most car camping scenarios.

All-Season/Expedition: Maximum Protection

For harsh conditions, invest in the highest-performing materials available. Cuben fiber with full seam sealing provides the ultimate protection, while silicone-coated fabrics offer excellent performance at a more reasonable price.

Environmental concerns are driving innovation in tent fabric materials. RPET fabrics made from recycled plastic bottles reduce waste while providing decent waterproof performance. Some manufacturers now offer bio-based PU coatings that break down more safely at end-of-life.

Consider the full lifecycle of your tent when making a purchase. Higher-quality, more durable materials may cost more initially but reduce environmental impact over time by lasting longer and avoiding premature replacement.

What is the most waterproof tent material?

Cuben fiber (Dyneema Composite) offers the highest waterproof ratings, typically exceeding 6000 mm HH. However, silicone-coated nylon provides excellent performance at 4000–5000 mm HH with better value and durability for most users.

How much HH do I need for a 3-day downpour?

For extended heavy rain, look for fabrics with at least 4000 mm HH rating. Materials with 2000–3000 mm ratings may eventually wet out during prolonged exposure to driving rain, especially if there's wind pressure involved.

Can I re-apply waterproof coating myself?

Yes, but it depends on the original coating type. Silicone coatings can be refreshed with silicone-based sealers, while PU coatings are more difficult to restore once they begin breaking down. Prevention through proper storage and care is more effective than trying to restore degraded coatings.

The most waterproof tent material isn't necessarily the best choice for every camper. Cuben fiber offers unmatched performance but comes with a premium price tag. Silicone-coated nylon provides excellent waterproofing with good value for serious outdoor enthusiasts. PU-coated polyester works well for casual camping at budget-friendly prices.

Consider your camping style, budget, and performance needs when selecting your next tent. Remember that proper setup, maintenance, and complementary gear like footprints can significantly improve any tent's waterproof performance.

The right tent fabric will keep you dry and comfortable, letting you focus on enjoying your outdoor adventures regardless of what weather comes your way.